In today’s business world filled with uncertainty, risks in the supply chain can arise at any moment, whether it is transportation issues, raw material shortages, natural disasters, or economic volatility. These disruptions can stop production and delivery, affecting revenue and customer trust. This is why Supply Chain Risk Management (SCRM) has become essential for every business. It refers to the process of identifying, assessing, and mitigating risks within the supply chain to ensure continuity and resilience. If you want to start understanding the risks in your own system, beginning with a risk assessment will help you gain a clear overview and identify weaknesses that need improvement.

What is Supply Chain Risk Management ?

Supply Chain Risk Management is the process of identifying, assessing, and managing risks that may occur throughout the supply chain from upstream (suppliers) to downstream (customers). The goal is to minimize the impact of unexpected events and maintain continuous operations. Risk management in the supply chain doesn’t mean avoiding all risks but rather being prepared to respond and having contingency plans in place. This ensures that the business can continue operating even during a crisis.

What Are the Supply Chain Risks Businesses Should Know ?

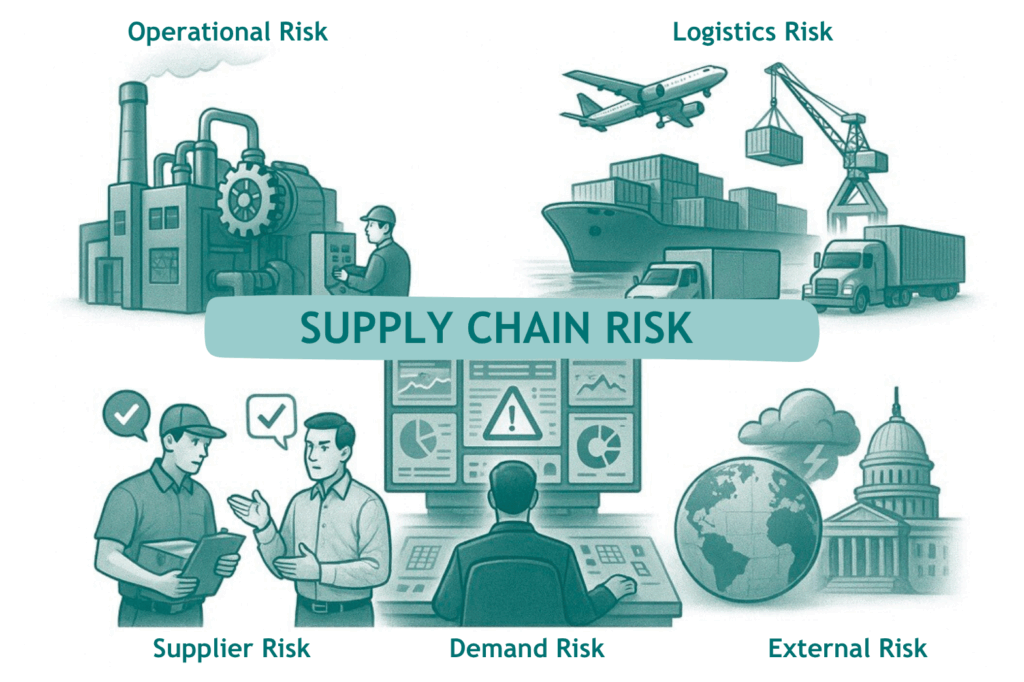

Supply Chain Risk refers to potential risks that can occur throughout the supply chain, which consists of multiple stages and numerous stakeholders. Each stage has the potential to impact business continuity. Without proper management, these risks can lead to disruptions and serious damage to the organization. Understanding supply chain risks is the first and most crucial step toward effective prevention. These risks can be categorized as follows:

-

Operational Risks:

Issues in production processes, machinery breakdowns, or IT system failures. -

Supplier Risks:

Suppliers failing to deliver on time or providing materials that do not meet quality standards -

Logistics Risks:

Transportation delays, customs issues, or fluctuating shipping costs. -

External Risks:

Natural disasters, wars, changes in government policies, or global economic shifts. -

Demand Risks:

Inaccurate sales forecasts leading to excess or insufficient inventory.

Why Is Supply Chain Risk Management Important for Businesses ?

Managing risks in the supply chain is not just about minimizing damage, it is a strategic approach that strengthens long-term business resilience. Its importance includes:

Reducing the Risk of Production Disruptions

Even short production stops can cause significant financial and reputational damage. A risk management system and contingency plan help identify vulnerabilities and keep operations running despite disruptions

Maintaining Customer Satisfaction

Customers expect timely delivery and consistent quality. Delays or quality issues can destroy trust. Effective risk management builds confidence and enhances customer experience.

Enhancing Competitive Advantage

Businesses that can quickly respond to changes have an edge over competitors. Analysis and preparedness allow for agile operational adjustments.

Lowering Costs and Driving Long-Term Returns

While investing in risk management systems may incur initial costs, it reduces losses and unexpected expenses over time, while improving resource efficiency.

Building Trust and Attracting Sustainable Partnerships

Demonstrating a clear and effective risk management system reassures partners of your capability, encouraging long-term collaboration and investment.

What Are the Approaches to Supply Chain Risk Management ?

Supply Chain Risk Management is a process that requires systematic planning, covering everything from risk identification, impact assessment ( BIA ), to the determination of measures to reduce and control risks. Generally, the main approaches can be divided as follows:

Operational Risks

These risks stem from internal issues such as machinery breakdowns, labor shortages, or IT system failures. Preventive strategies include:

- Implementing preventive maintenance plans

- Having backup machinery or alternative production sites

- Using real-time production and supply chain tracking systems

Global Risks

These involve external factors from international sources, such as political instability, trade regulations, or legal changes in partner countries. Strategies include:

- Diversifying suppliers across multiple regions to reduce dependency

- Monitoring news and analyzing trends in laws and taxation

- Planning alternative transportation routes and methods

Economic Risks

These arise from economic downturns, raw material price fluctuations, or exchange rate changes. Mitigation strategies include:

- Long-term contracts for raw materials to stabilize pricing

- Setting aside emergency budgets

- Analyzing costs and identifying ways to reduce unnecessary expenses

Natural Risks

These include events like floods, earthquakes, storms, or wildfires that can disrupt transportation and production. Preventive measures include:

- Planning backup logistics routes

- Develop a Business Continuity Plan (BCP) that covers disasters.

- Purchasing insurance that covers damage from natural events

Consult Supply Chain Risk Management With InterRisk Asia

At InterRisk, we have a team of experts specializing in supply chain risk assessment and management. We use an integrated approach from process analysis and supplier readiness audits to designing a comprehensive Business Continuity Plan (BCP). If you are looking to enhance the security of your supply chain and gain a competitive edge, contact our expert consultants at InterRisk Asia today, and rest assured that “your organization remains operational, even in times of crisis”.

InterRisk Asia is a leading business continuity consulting firm in Thailand, operates under the MS&AD Group from Japan.

End-to-end consulting for the development of a robust BCMS, with pathways to ISO 22301 certification

Specialized training programs designed for both management and staff to enhance awareness and competency in BCMS practices.

Analysis of operational risks and disruption impacts to inform the development of targeted continuity strategies.

Structured exercises to validate your BCP and strengthen organizational preparedness and response capabilities.

Experienced consultants with hands-on BCMS expertise

Customized planning tailored to your business context.

Practical tools and templates, with expert support for testing and improvement.